What are SMT Spring Finger Contacts?

What are SMT Spring Finger Contacts?

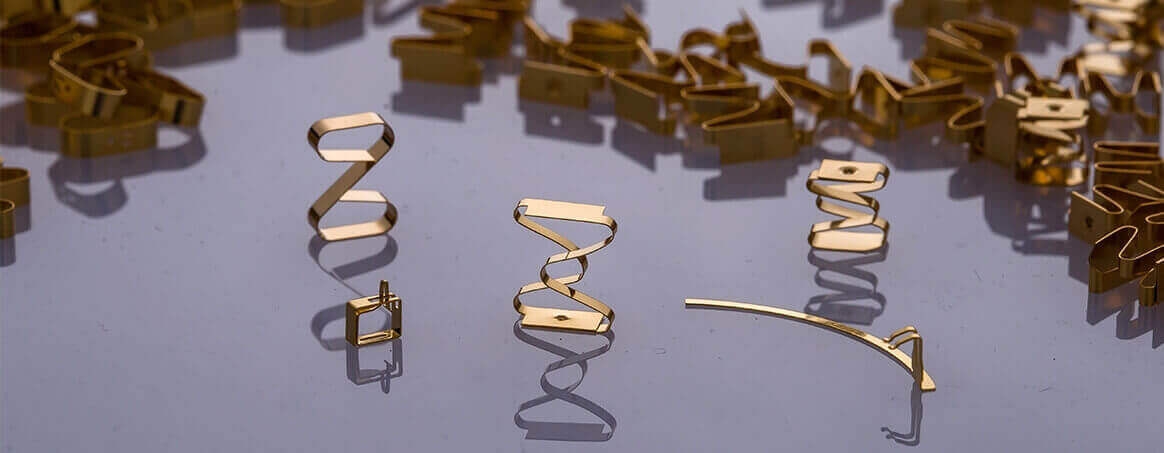

SMT spring finger contacts have various names based on their purposes. They can be called EMI clips, spring fingers, EMI contact fingers, PCB spring contacts, etc. Spring finger contacts are small mechanical parts, usually only a few millimeters (mm) in size, commonly installed and configured for connection or grounding in electronic devices. Spring fingers contacts are widely used in embedded system projects, such as sensors for medical applications, battery connectors for electric bicycles, car dashboards and headlights, and weapons or vehicles for military applications.

Spring finger contacts are used as connectors for electrical contact with printed circuit boards (PCBs) for the purpose of circuit grounding, along with electromagnetic interference (EMI) noise and static electricity prevention. They are regarded as simple, stable and cost-efficient mechanical parts that establish reliable contact between two PCBs or a PCB to the chassis even in harsh environments including conditions of vibration, extreme temperatures and humidity. Our SMT contacts come in a variety of shapes and sizes for customers to choose from to address all sorts of needs or requirements.

The most common spring finger contacts in the market are made of beryllium copper, which is a type of copper alloy known for high strength, thermal and electrical conductivity. It possesses excellent machining properties that can withstand repeated use more than hundreds of thousands of times. The second most common material for spring finger contacts is stainless steel, which is cheaper in cost yet lower in conductivity and machining durability than beryllium copper. Although there are other alloy metals to choose from, they are not recommended as viable replacements given the fact that beryllium copper is considered the best by far in terms of performance and effectiveness. As for surface coating, the best option is to use nickel as the base with gold plating on the surface. Nickel has a superior oxidation resistance with high weldability even in high-humidity environments. Meanwhile, gold has a high resistance to extreme temperatures and high humidity, with great conductivity and high corrosion-resistance, making it an ideal material for surface treatment.

Spring finger contacts can be used for grounding or PCB connection. The recommended compression ratio of the SMT contacts is 20-40% of the total height. These spring fingers can withstand tens of thousands of mechanical cycles in use with strong vibration resistance, which makes them ideal for applications in military, automotive and other industries. Based on customer requirements, we provide bulk packaging or tape and reel packaging, with the latter widely applied in automated installation. While we currently have more than 300 types of standard SMT contacts in stock, we also accept customization inquiries and requests. If you have any needs for spring finger contacts, please feel free to contact us at sales@oscarprecision.com