EMI Spring Contacts

EMI Spring Contacts

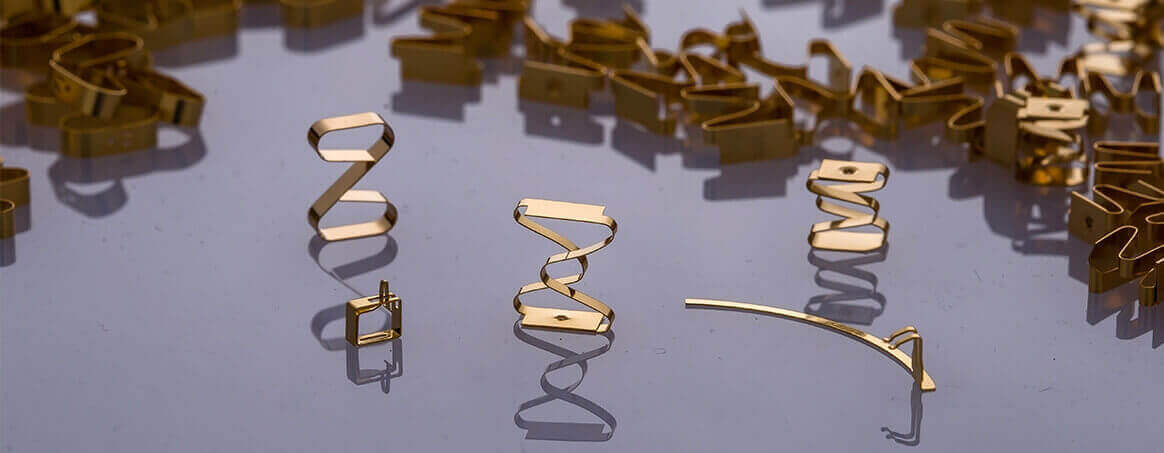

The increasing demand for electronic devices has led to a higher demand for more intricate electrical internal connections, which undoubtedly has become a greater challenge for engineers and designers. The greatest challenge in design is the various electromagnetic wave interference (EMI) generated from operation of electronic equipment with the external connectors. In order to overcome problems resulted from electromagnetic interference, EMI spring contacts could be applied as an effective, stable and cost-efficient solution.

EMI spring contacts, also called universal ground contacts、SMD EMI fingers、spring fingers or shielding shrapnel. These kinds of EMI shielding products (and/or RFI shielding products) can be used for withstanding disturbance from antennas, motors, speakers, microphones, etc., or for grounding between equipment and PCBs (printed circuit board). It is widely used in mobile handheld devices, antenna connection, wireless equipment, internet of things, industrial equipment or home entertainment systems, etc.

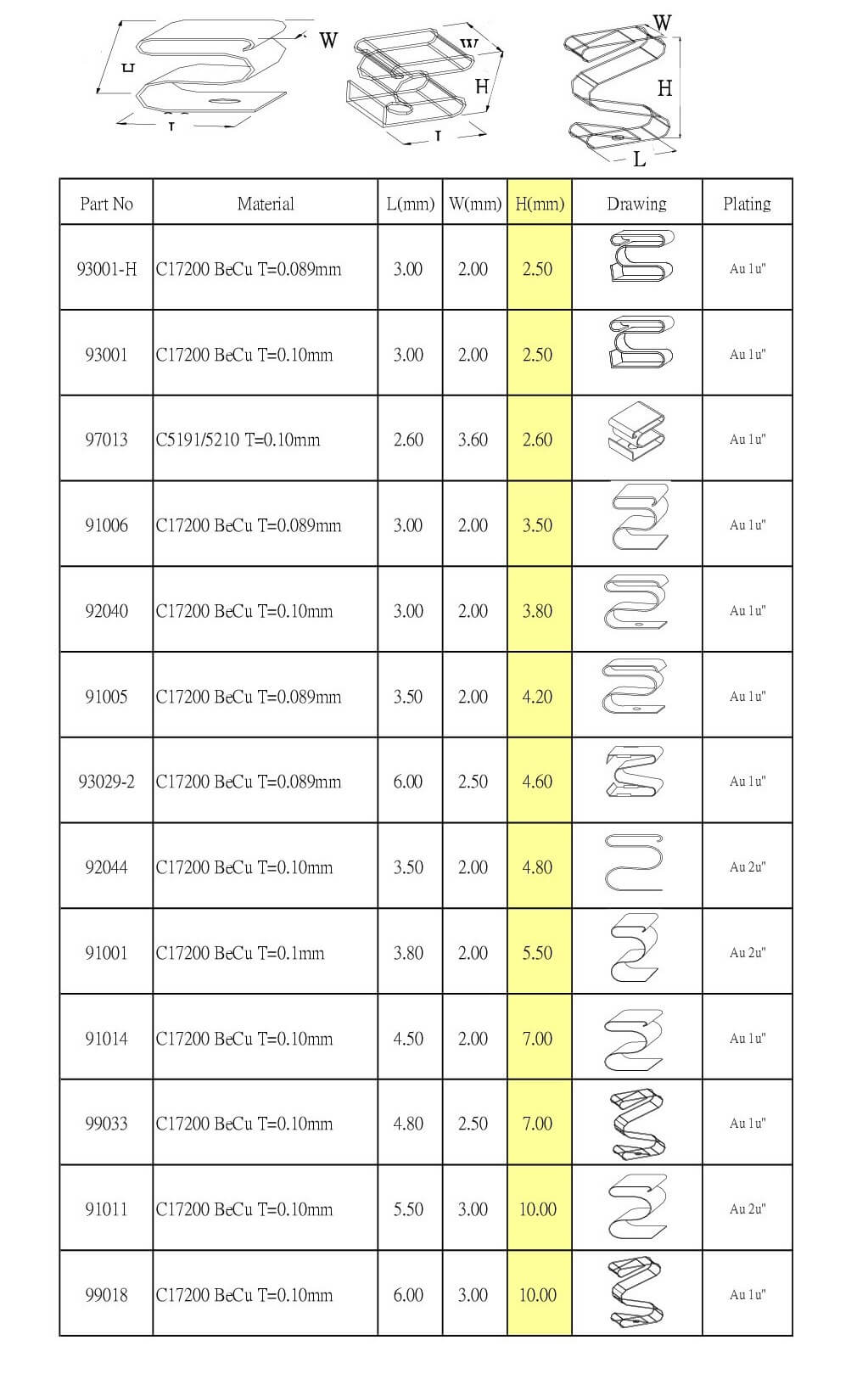

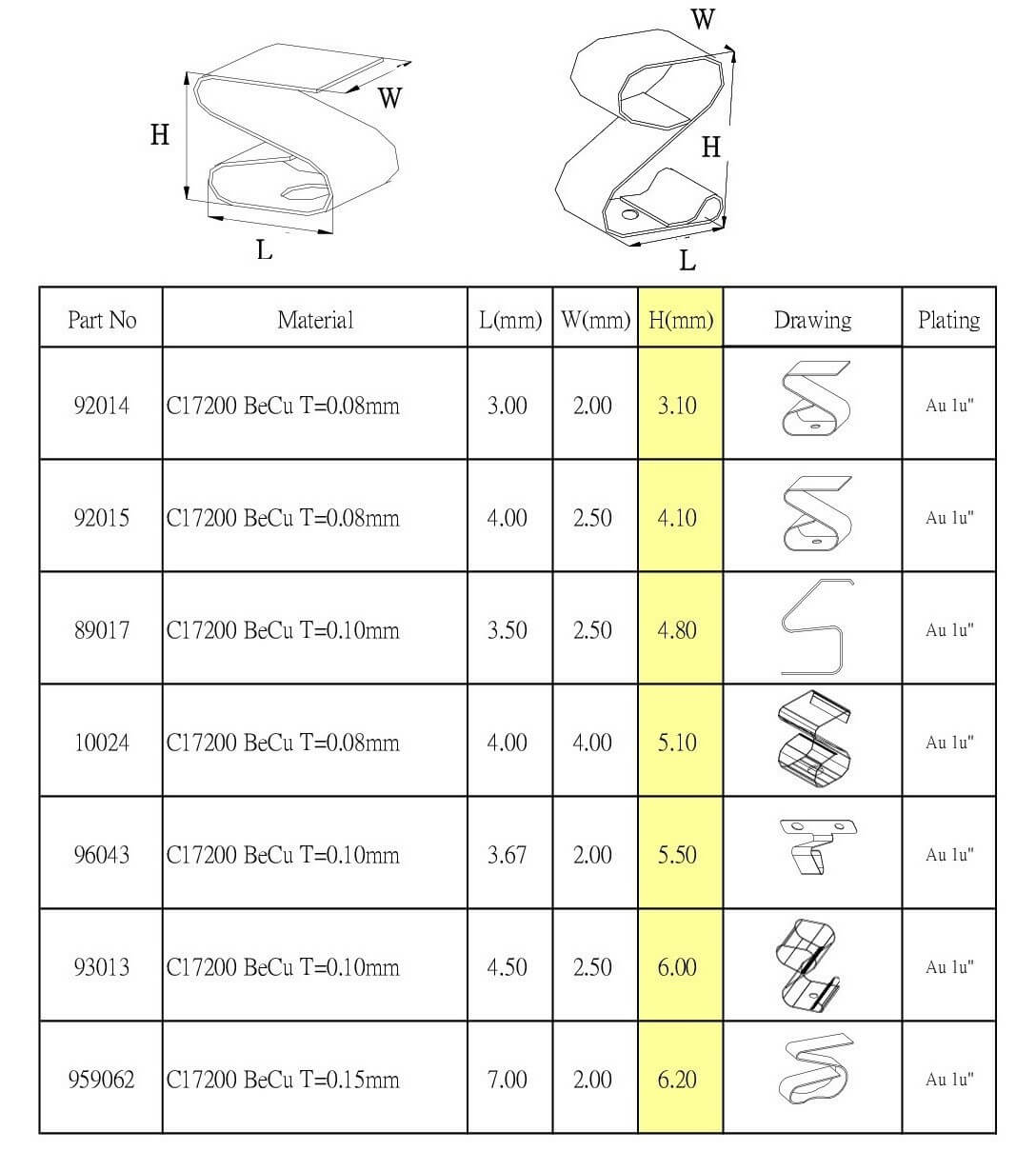

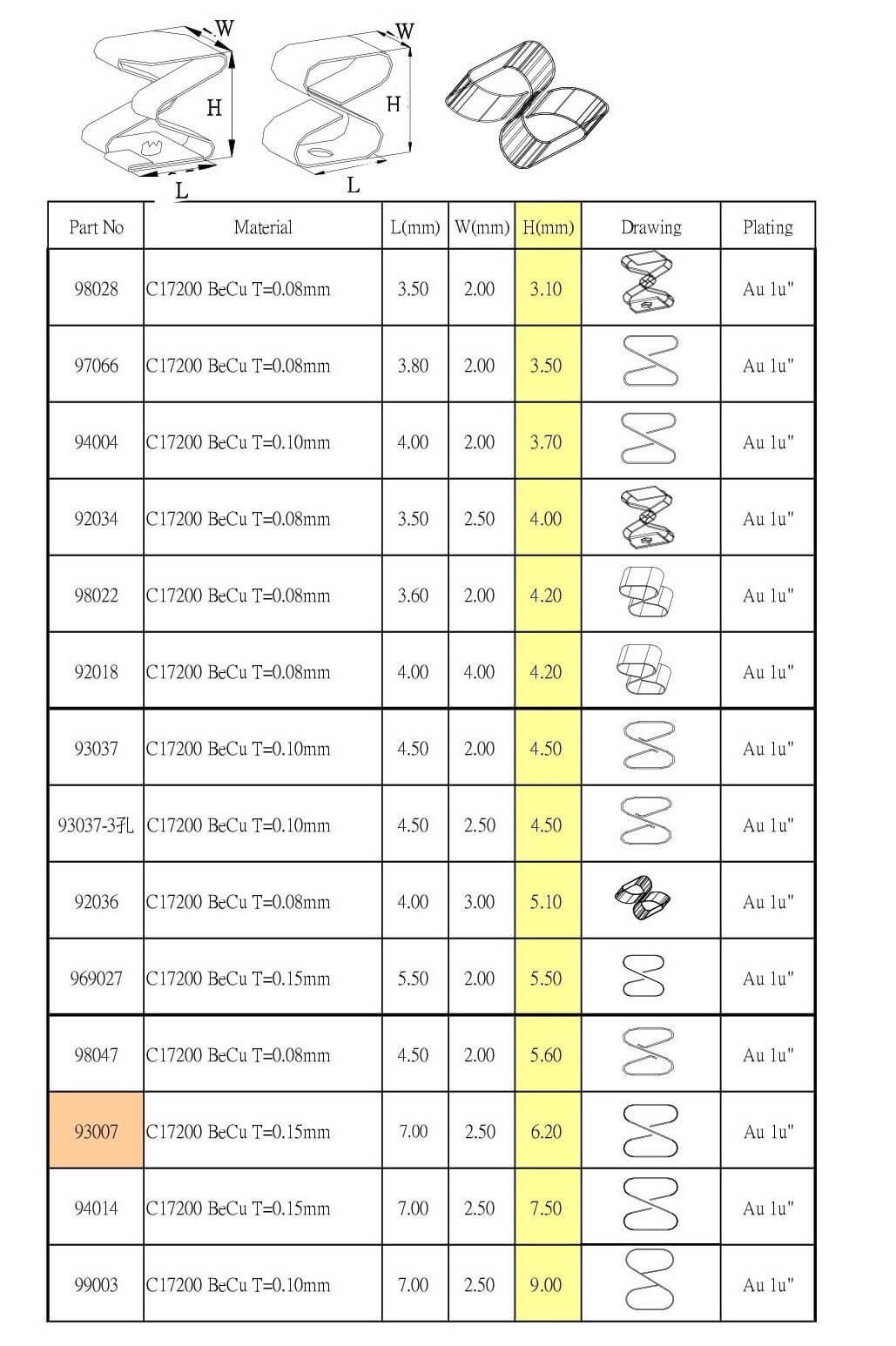

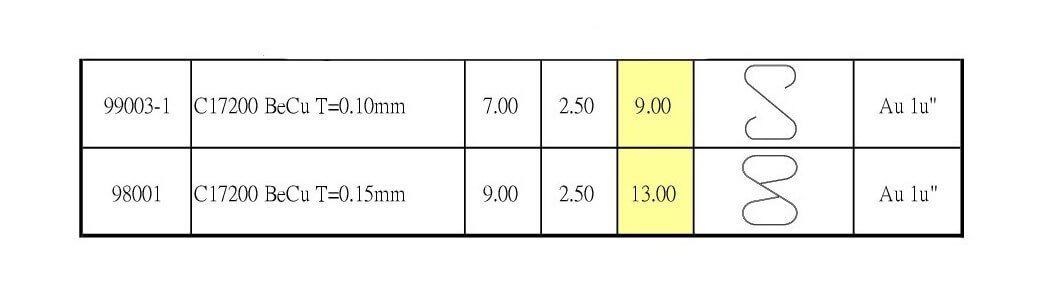

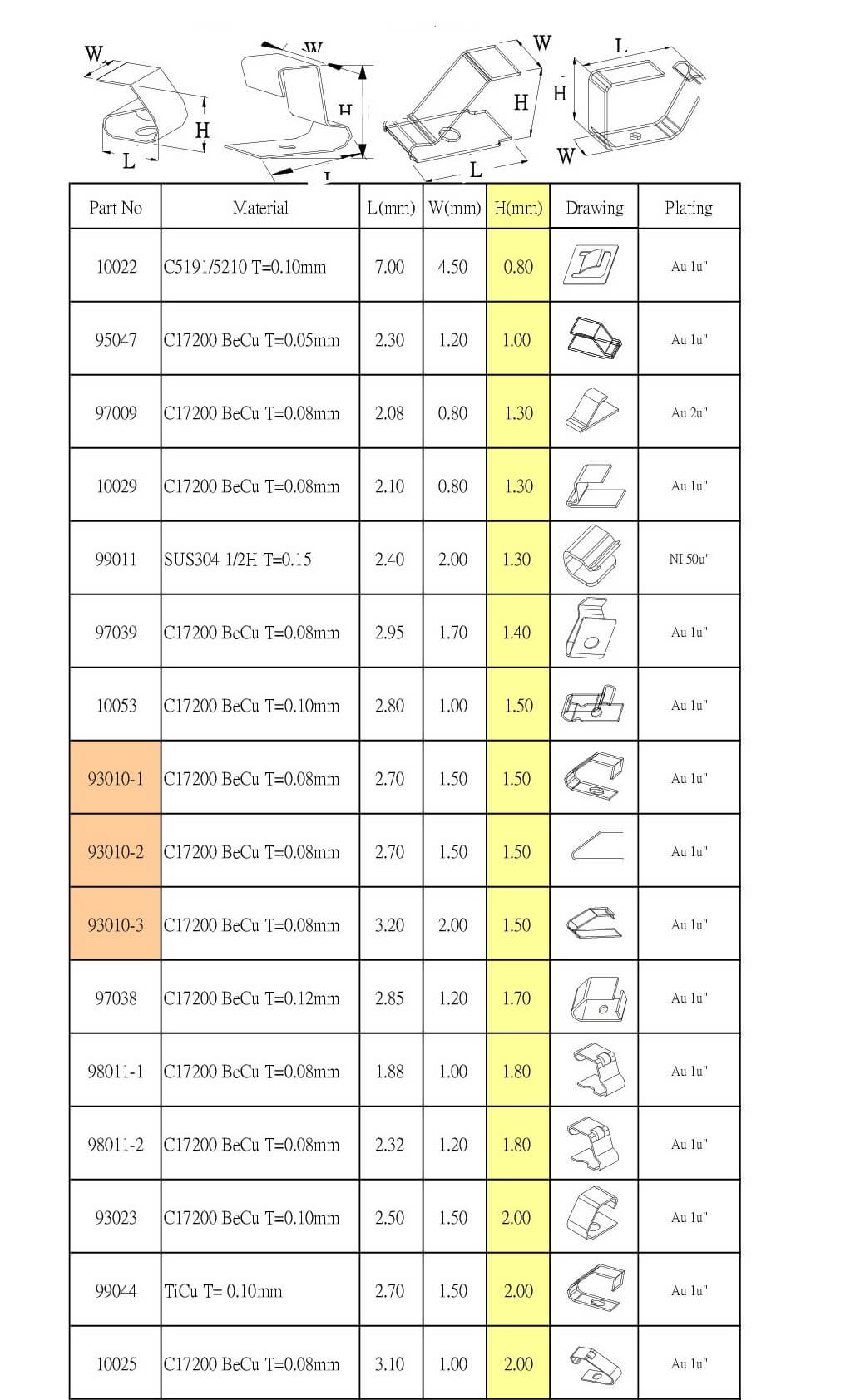

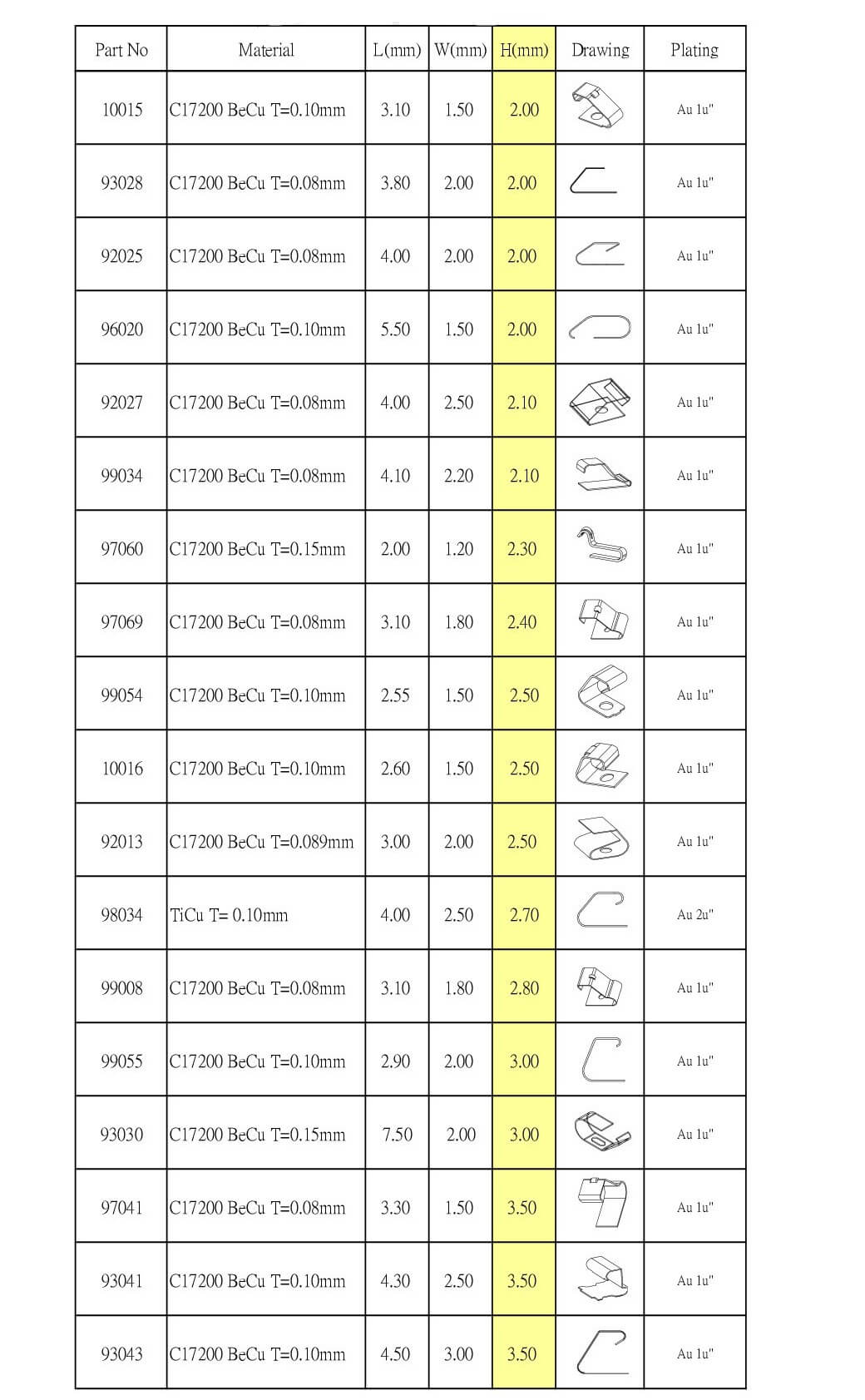

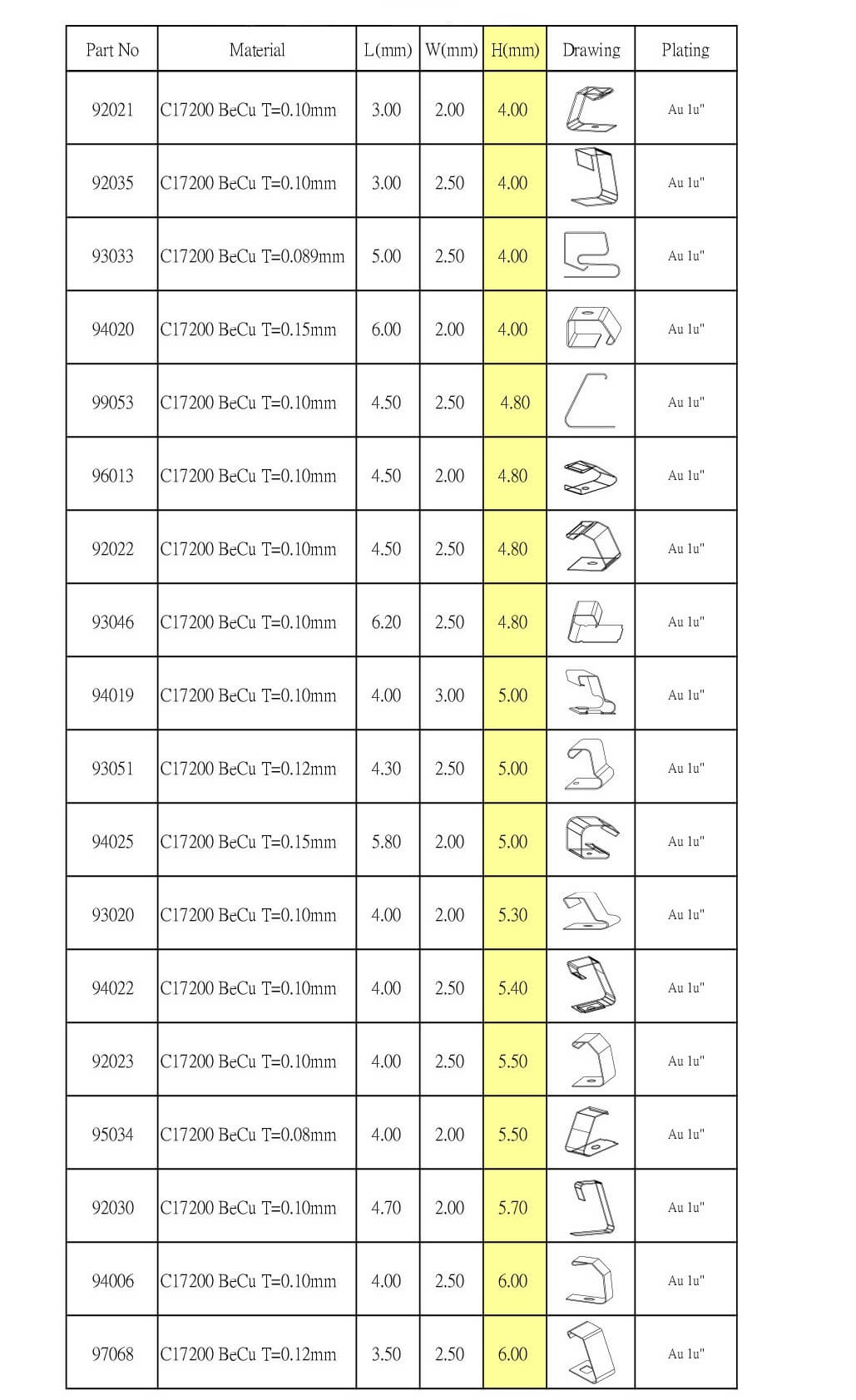

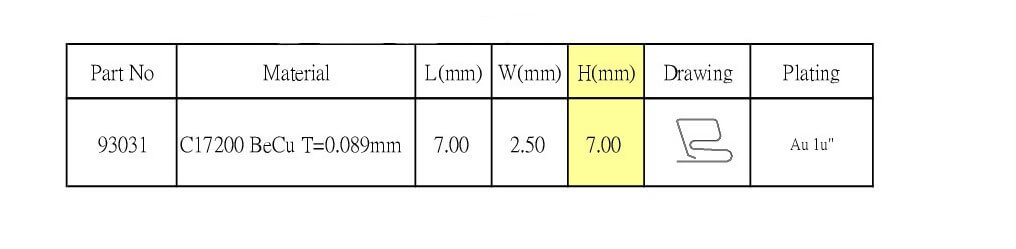

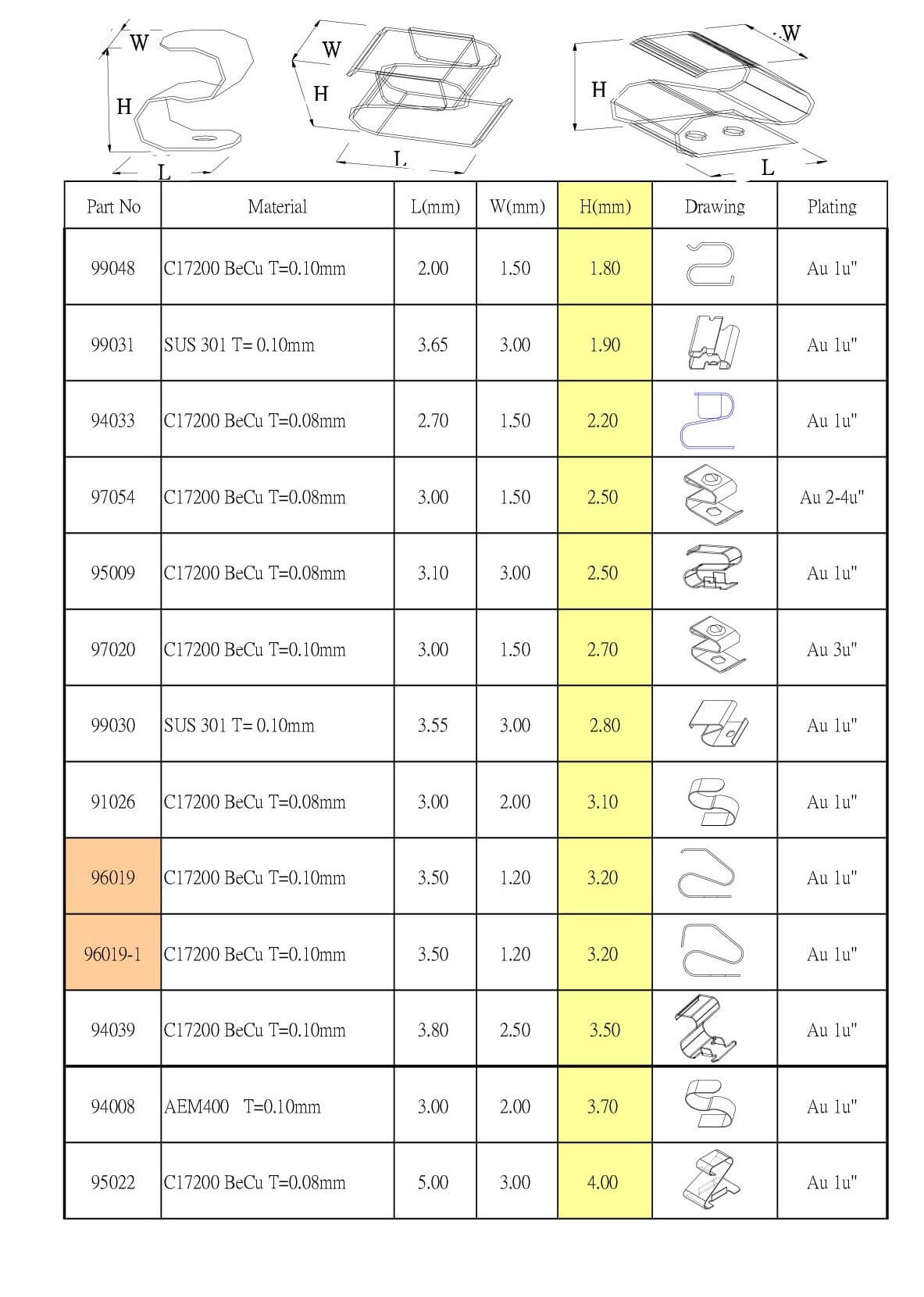

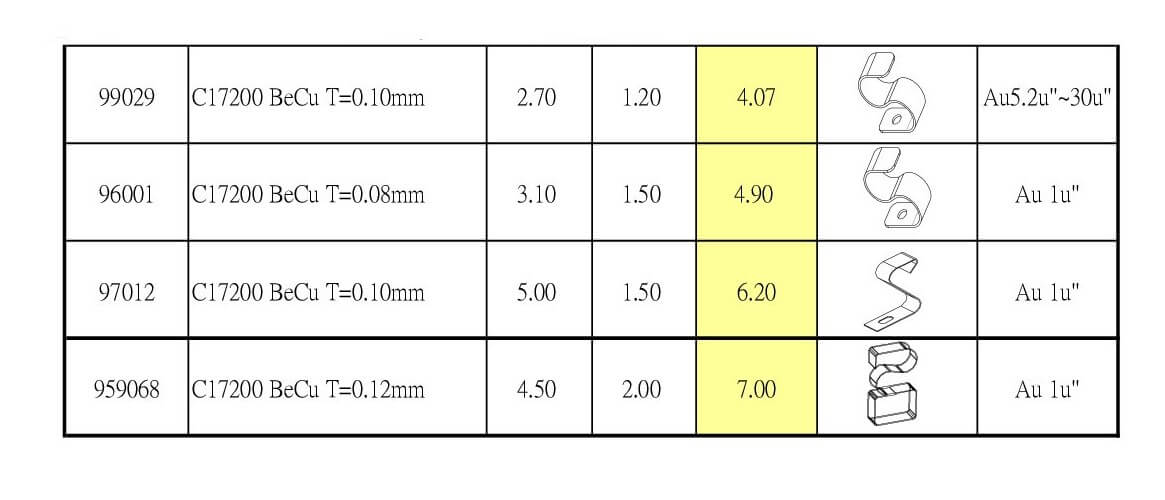

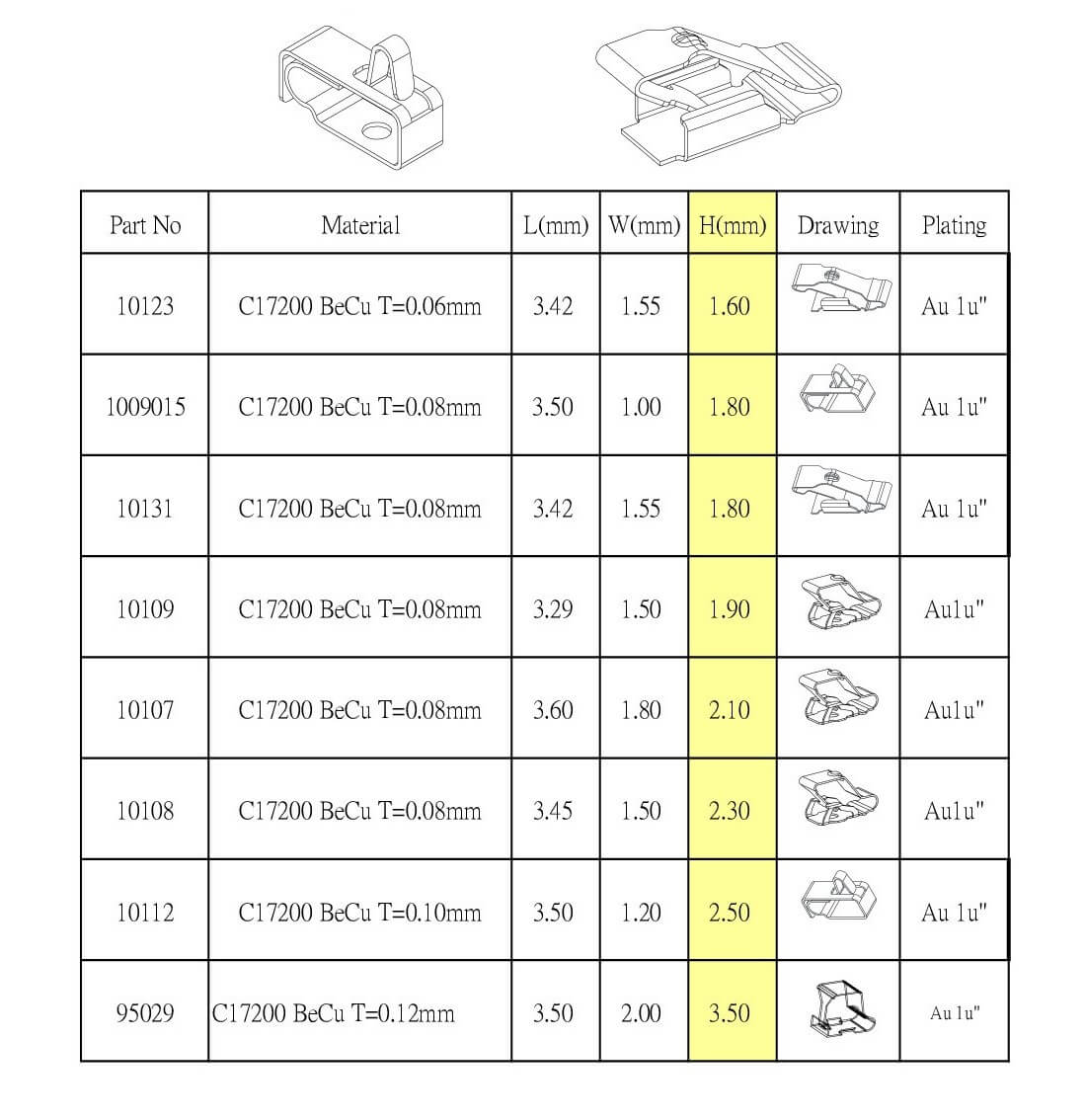

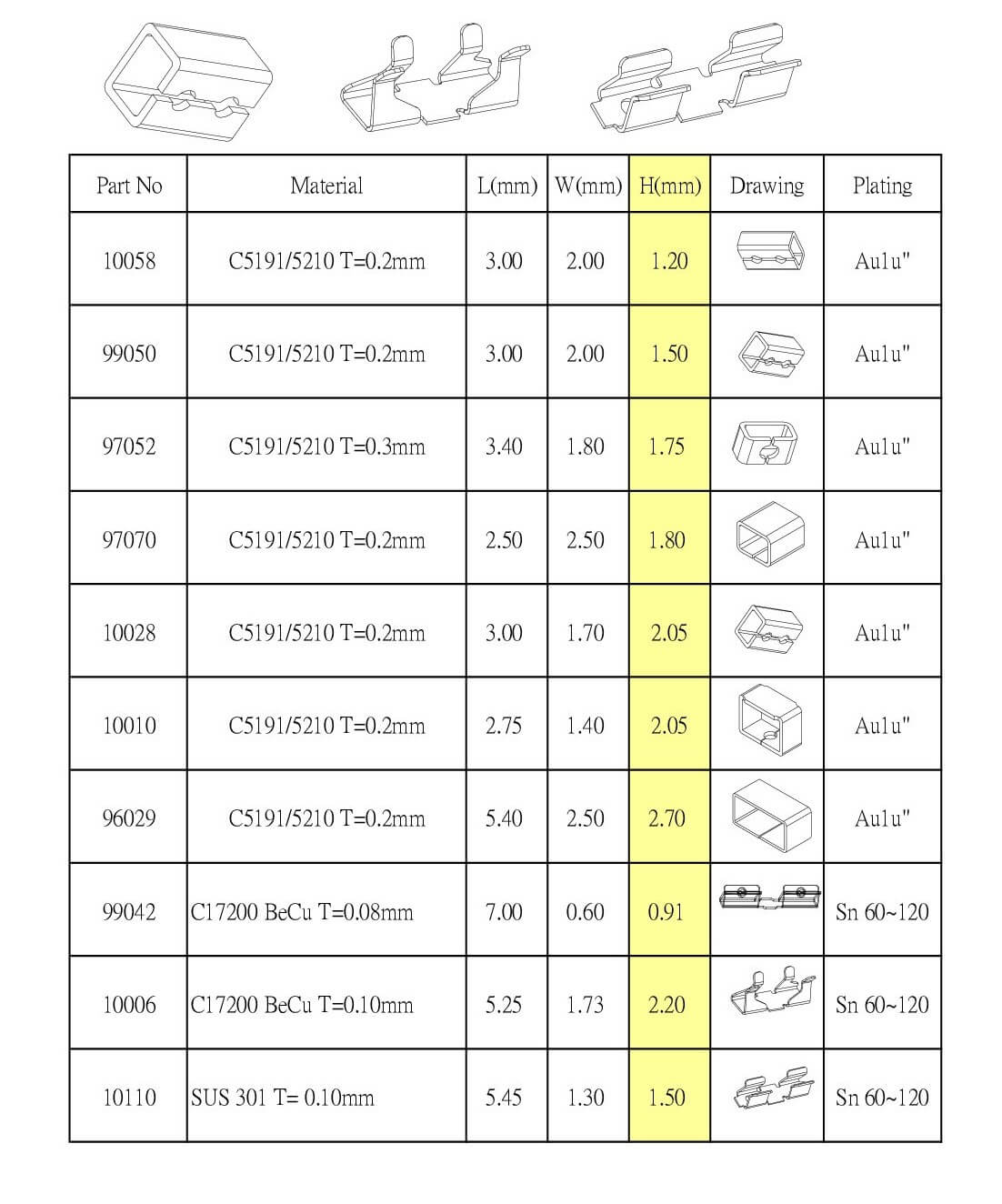

Better performance of electronic components requires release of unwanted electromagnetic interference (EMI) from specific parts of the PCBs, or use of grounding devices for a better control of magnetic and electronic fields. EMI/RFI shielding products are designed to prevent or reduce electromagnetic interference, to shield reflections, and to absorb incident radiation. The higher the attenuation of the shield, the more effective it is in suppressing or blocking unwanted electromagnetic interference. With more than 50 kinds of standard models ready to ship, we also provide customized EMI spring contacts in various shapes and with desired materials according to customer requirements. For instance, Beryllium copper EMI shielding products, plated with gold on the surface, can lower electrical resistance and provide protection with corrosion resistance. Its no-sharp-angle design can avoid scratching other parts, while the hole at the bottom can increase the welding strength required for its installation on a PCB, it allows use of standard equipment for soldering and easy placement or replacement.

To meet customer requirements, we can provide bulk packaging or tape and reel packaging for easier automated assembly. The CCD detector our company developed can be used to automatically inspect each finished product based on customer specifications in order to achieve the highest production yield. We have developed many sets of molds and standardized products with the height ranged from 0.8mm to 13mm that are ready to ship and can be applied to almost any design. We can also provide customized services tailored to the needs of individual customers that require assistance in design, product development and prototype manufacturing. Our goal is to help our customers significantly reduce design costs, shorten production cycle for an earlier successful release, and increase profit margins. If you have any inquiries about our products and services, please do not hesitate to contact us at sales@oscarprecision.com.